Cultivator Finisher

The Finisher is a versatile tool for shallow and medium-depth tillage. The combination of working bodies and their arrangement allow the tool to be used efficiently in first post-harvest tillage or in minimisation technologies where a higher proportion of crop residues is expected. The high stiffness of the hydropneumatically secured coulters and the weight of the machine allow the soil to be worked down to a depth of 35 cm.

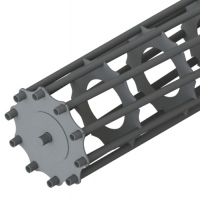

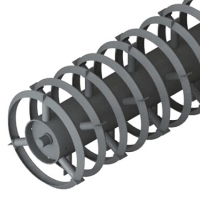

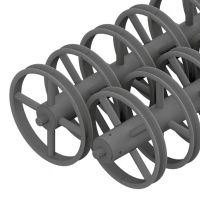

The machine combines several working operations in one pass. The front disc section takes care of shallow subsoiling and cutting of crop residues. This is followed by a section with three rows of tines for deep tillage up to 35 cm and mixing of the soil profile. Behind them is a section for backfilling the soil with levelling pens or discs, and a support roller to level the soil rounds off the whole thing. The high weight of the machine and the new modern concept guarantee medium-depth soil cultivation from the first pass over the field.

The new (third) generation of the machine was introduced in autumn 2023. The new models have replaced the original double-wound spring-loaded overload protection skids with a hydropneumatic non-stop type, thereby increasing the working depth to 35 cm. The spacing of the working sections has also been extended, reducing the risk of clogging with plant debris.

- Disc diameter 51 cm

- Disc distance 125 mm

- 3 rows of chisel shares with an axial distance 310 mm (model 400 and 520) or 325 mm (model 300)

- Working depth up to 35 cm

- Working speed up to 15 km/h

Advantages

- Robust and quality designed frame construction made of 120x120x8 steel profiles

- Easy maintenance guaranteed by reliable components from top suppliers

- Easy machine operation/setup - everything is controlled by hydraulics

- Maximum material throughput thanks to the arrangement of the ploughshares in 3 rows

- Possibility of adjusting the stiffness of the hydropneumatic plough clamping in the range of 400-700 kg

- Choice of a wide range of support rollers

- Choice of a wide range of wear parts

Machine construction:

Model 300: Semi-carried, rigid, one-piece frame

Models 400 and 520: Semi-carried, hydraulically folded, two-part frame

Version | 300 | 400 | 520 |

|---|---|---|---|

Min. power output (kW) | 180 | 230 | 280 |

No. of discs | 22 | 36 | 44 |

No. of tines | 9 | 13 | 17 |

Max. working depth (cm) | 35 | 35 | 35 |

Transport width (mm) | 3000 | 2800 | 2800 |

Working width (mm) | 300 | 415 | 540 |

Tire size | 19/45-17 | 550/45-22,5 | 550/45-22,5 |

Weight* | 3500 | 5300 | 5700 |

Lenght (mm) | 9400-9900 | 9400-9900 | 9400-9900 |

Working speed (km/h) | 8-14 | 8-14 | 8-14 |

Transport speed (km/h) | 30 | 30 | 30 |

Brake system | no | yes | yes |

Linkage type | swing eye ø 51 | swing eye ø 51 | swing eye ø 51 |