Disc harrows Huron

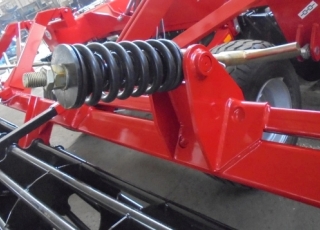

Disc harrows HURON is characterized by classic arrangement of working sections in X shape layout. The machine impresses with robust design and structurally simple frame which ensures reliability and long life of the machine. Folding into transport or working position is simple and intuitive as well as adjusting of working sections especially settings of disc angle and working depth.

Machine is suitable for stubble cultivation in classical agrotechnical process or for deeper cultivation in minimalization technologies as well as pre-seeding soil preparation after ploughing. High leveling effect of the machine seems to be very important from user´s point of view. Foldable version has the extra option to hydraulically lock sections into the precise level. Machine weight can be increased by adding water content into the frame profiles which enables sufficient work even under more challenging conditions.

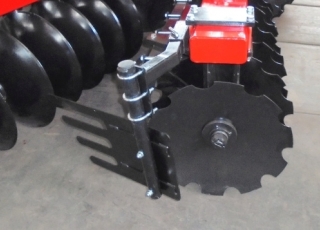

Large plates with 660 mm diameter are the main working units. The first row is fitted with carved plates for easier soil penetration. Disc assembly in compact section mounted on one shaft guarantees high throughput of plant residues. In case of a disc clog up, blocking material is pushed through the section by the other discs mounted on the same shaft.

- Disc diameter 66 cm

- Axis disc diameter 23,6 cm

- Working depth up to 20 cm

Advantages

+ Robust and quality designed frame construction

+ Very high throughput of soil and plant residues through the machine

+ Outstanding stability at high operation speed due to axle position in front of roller

+ Easy maintenance due to minimum points for lubrication

+ Symmetrical disc arrangement ensures accurate machine guidance in a tractor's direction

+ Easy control and machine setting

+ Ability to work in challenging and dry conditions

Machine desing

| Version 250 - 350 | rigid, semi-carried, one-part frame made of 100x100x8 mm profiles, 3 working positions |

| Version 400 - 500 | hydraulically folded, semi-carried, one-part frame made of 200x300x8 mm, continuously adjustable working angle |

| Version 500T - 700T | hydraulicky skládaný, polonesený, dvoudílný rám z profilu 200x300x8 mm, continuously adjustable working angle |

250 | 300 | 350 | 400 | 450 | 500 | 500 T | 600 T | 700 T | |

|---|---|---|---|---|---|---|---|---|---|

No. of discs | 20 | 24 | 28 | 36 | 40 | 44 | 44 | 52 | 60 |

No. of bearings | 8 | 8 | 8 | 8 | 12 | 12 | 12 | 14 | 16 |

Min. power output (kW) | 70 | 80 | 90 | 100 | 110 | 130 | 130 | 150 | 180 |

Weight per disc (kg/disc) | 95 | 90 | 84 | 127 | 121 | 116 | 135 | 131 | 133 |

Working width (cm) | 250 | 300 | 350 | 400 | 450 | 500 | 500 | 600 | 700 |

Transport width (mm) | 2700 | 3000 | 3510 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

Max. working depth (cm) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

Size of tires | 10,0/75-15,3 | 10,0/75-15,3 | 10,0/75-15,3 | 19/45-17 | 19/45-17 | 19/45-17 | 400/60-15,5 | 400/60-15,5 | 400/60-15,5 |

Working speed | 9-13 | 9-13 | 9-13 | 9-13 | 9-13 | 9-13 | 9-13 | 9-13 | 9-13 |

Transport speed | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

Brakes | - | - | - | on request | on request | on request | on request | on request | on request |

Hitch category | II | II | II | III | III | III | III | III | III |